Hot Air / Stirling Engine Workshop

About the Stirling Engine Workshop

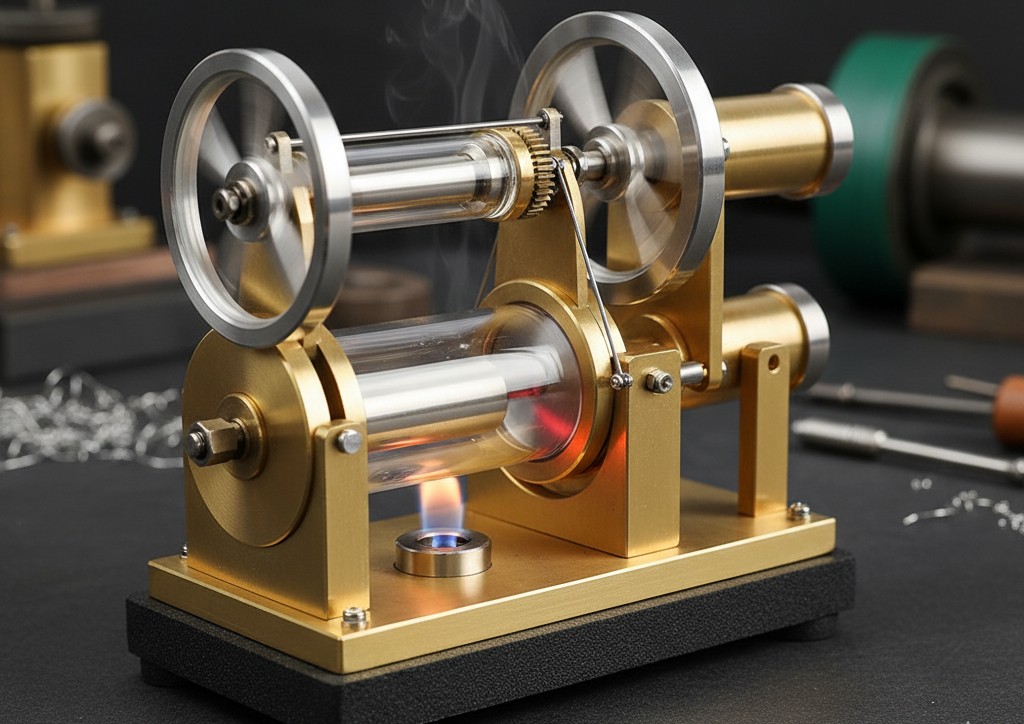

The Hot Air / Stirling Engine Workshop is a fully practical, hands-on training designed

to teach participants how Stirling engines work, how heat converts into mechanical motion, and how to

assemble and operate a complete functional Stirling engine model.

This workshop is ideal for engineering students, science enthusiasts, makers, and anyone interested in

classical thermodynamics and mechanical innovation. By the end of the workshop, every participant will

assemble, test, and operate a real Stirling engine while understanding its working principles.

🧩 Workshop Modules – Stirling Engine Workshop

📘 Thermodynamics & Operating Principles

Learn the complete theory behind Stirling engines, including hot-air expansion, cooling contraction, pressure cycles, displacer-piston coordination, and heat–mechanical energy conversion. Concepts are explained practically with real working models.

🔧 Hands-On Engine Assembly

Assemble a Stirling engine from scratch: frame setup, flywheel installation, crankshaft linkage, piston alignment, heating chamber placement, lubrication, and precision balancing for smooth motion.

🧪 Testing & Performance Tuning

Learn heating techniques, flame control, rotational testing, RPM improvement, friction reduction, air leakage checks, and efficiency optimization to achieve smooth and stable engine operation.

🔥 Safe Operation & Handling

Understand how to safely operate Stirling engines, manage heating sources, prevent overheating, maintain spacing, and practice correct startup and shutdown procedures.

⏳ Workshop Duration

The workshop typically spans 3 to 4 days, covering:

Day-1: Thermodynamics & basic theory

Day-2: Engine assembly

Day-3: Assembly & Testing

Day-4: Advanced concepts

📘 What You Will Learn in the Stirling Engine Workshop

🔥 Thermodynamics & Heat Cycles

Understand how heat is converted into mechanical motion, Stirling cycle working, expansion–compression phases, temperature gradients, energy transfer, and efficiency concepts.

⚙️ Mechanical Assembly & Alignment

Learn how to assemble key components such as flywheel, crankshaft, piston, displacer cylinder, connecting rods, bearings, and support structures with proper alignment and lubrication.

🔥 Heat Source Management

Study safe heating techniques, flame control, temperature handling, and maintaining optimal heat input to achieve smooth and continuous engine rotation.

🔩 Materials & Thermal Behavior

Learn why specific metals and components are used, how thermal expansion affects motion, and how to avoid heat stress or deformation in engine parts.

🛠 Engine Assembly & Fine-Tuning

Assemble the full Stirling engine, check tolerances, remove friction points, ensure airtightness, balance the flywheel, and tune the mechanism for maximum RPM.

🚀 Hands-On Engine Testing

Test engine startup, rotational smoothness, vibration control, heat-to-motion efficiency, and performance tuning under various temperature conditions.

🎯 Key Skills You Will Gain in the Stirling Engine Workshop

🔧 Hands-On Stirling Engine Assembly

Learn to assemble a complete Stirling engine—displacer cylinder, piston, crankshaft, flywheel, linkage rods, and frame structure with precision.

📘 Strong Understanding of Thermodynamics

Gain deep knowledge of heat cycles, pressure changes, expansion–compression, and how thermal energy converts into mechanical rotation.

🔥 Heat Input & Engine Operation

Learn how to safely apply heat, optimize temperature differences, start the engine smoothly, and maintain continuous operation.

⚙️ Engine Calibration & Balancing

Fine-tune piston motion, reduce friction, adjust tolerances, balance the flywheel, and achieve maximum mechanical efficiency.

🛠 Mechanical Motion & Linkage Mechanics

Understand how crank mechanisms, push-rods, bearings, and rotational systems work together to produce smooth cyclic motion.

🔍 Troubleshooting & Optimization

Identify thermal leaks, friction points, misalignment, air-tightness issues, and improve RPM through systematic tuning.

👥 Who Can Join the Stirling Engine Workshop?

🎓 Students

Ideal for school and college students interested in classical thermodynamics, mechanical systems, and hands-on engineering.

🛠 Hobbyists & Makers

Perfect for DIY enthusiasts who enjoy building mechanical models, experimenting with heat engines, and understanding how motion is generated.

🏫 Engineering Colleges

Highly suitable for Mechanical, Automobile, EEE, Mechatronics, and Aerospace departments focusing on practical engine mechanisms.

🤝 Technical Clubs & Innovation Cells

Great for mechanical clubs, project labs, innovation cells, and engineering forums looking for a practical working model build.

🔥 Engine & Thermodynamics Enthusiasts

Anyone curious about heat engines, Stirling mechanisms, or classical power-generation concepts can join and learn deeply.

🌟 Benefits of the Stirling Engine Workshop

🔥 Build a Working Stirling Engine

Every participant assembles, aligns, and tests a fully functioning Stirling engine that runs using heat-to-motion conversion principles.

👐 Complete Hands-On Experience

Learn by assembling mechanical parts, setting piston alignment, installing flywheels, and tuning the engine for smooth motion — 100% practical.

🛠 Mechanical Tools & Real Components

Work with precision tools, metal components, crankshaft systems, pistons, bearings, and heat chambers just like real mechanical engineering labs use.

📜 Certification of Completion

Receive an official workshop certificate from MMTimes, adding strong value to your resume, academic profile, or engineering portfolio.

💡 Thermodynamics & Innovation Insight

Gain a deep understanding of external combustion engines, heat transfer, energy cycles, efficiency concepts, and real-world engineering applications.

🤝 Team Collaboration Experience

Build and troubleshoot in teams, improving coordination, mechanical problem-solving, and hands-on engineering teamwork.

🚀 Future Scope — Stirling Engine Workshop

⚙️ Mechanical Engineering Pathways

Build strong foundations in mechanisms, heat engines, and machine design—skills helpful for careers in mechanical R&D, engine design, and thermal systems engineering.

🔥 Thermal & Energy Research

Explore opportunities in thermodynamic research, alternative energy systems, external-combustion engine studies, and renewable heat-to-power technologies.

🏭 Industrial Automation

Apply concepts of motion conversion, mechanical balancing, pistons, and linkages to industrial automation, machine design, and precision engineering.

♻️ Sustainable Energy Devices

Work on clean-energy projects using solar-heated Stirling engines, low-emission power systems, and experimental eco-friendly heat engines.

🔬 Scientific Prototyping

Gain confidence to build mechanical prototypes, perform thermal experiments, and design engines for educational or scientific demonstrations.

👨🏫 Teaching & Academic Opportunities

Use Stirling engines for classroom demonstrations, STEM education, lab activities, or mechanical project guidance as a teacher, mentor, or workshop leader.

💼 Startup & Maker Projects

Build miniature engines, DIY engineering kits, desk-toy engines, or custom mechanical devices as part of a product line or maker startup.

🔥 Ready to Build Your Own Stirling Engine?

Join the hands-on Stirling Engine Workshop and learn how to convert heat into motion by building and testing your own working external-combustion engine.